Drum Brake Pads

The commonly used drum friction plates on the market can be roughly divided into the following series:

YWZ 、YWK、TE、SHB、SBH、SHI、THI、LDM

1. MWBIG Introduce the “explosion-proof” element into the above models:

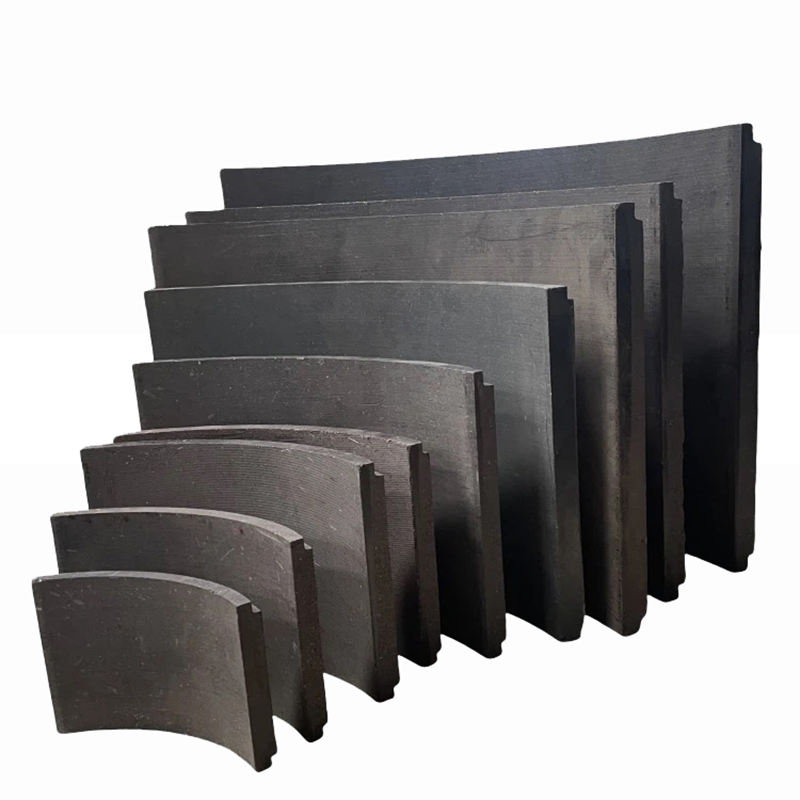

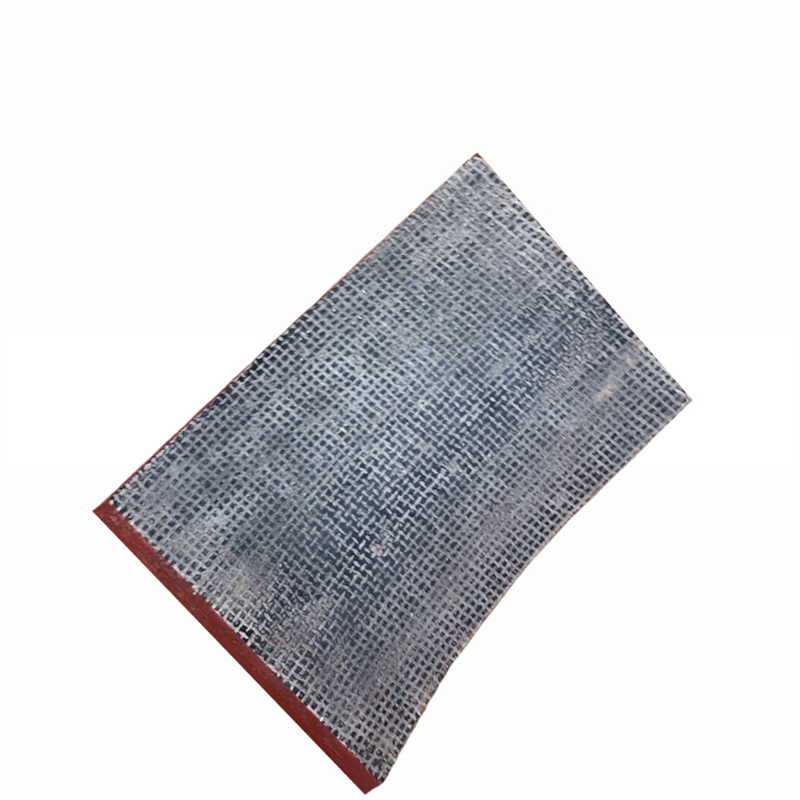

2. Drum blades with steel back

In modes such as super lifting and long lifting, the brake needs to maintain a tight and locked state for a long time, which puts a significant load on the friction plate. When the brake is released, the friction plate is prone to deformation

MWBIG has proposed a more suitable solution, which is to carry drum friction plates with drum shaped arc-shaped steel backboards, greatly reducing the probability of deformation

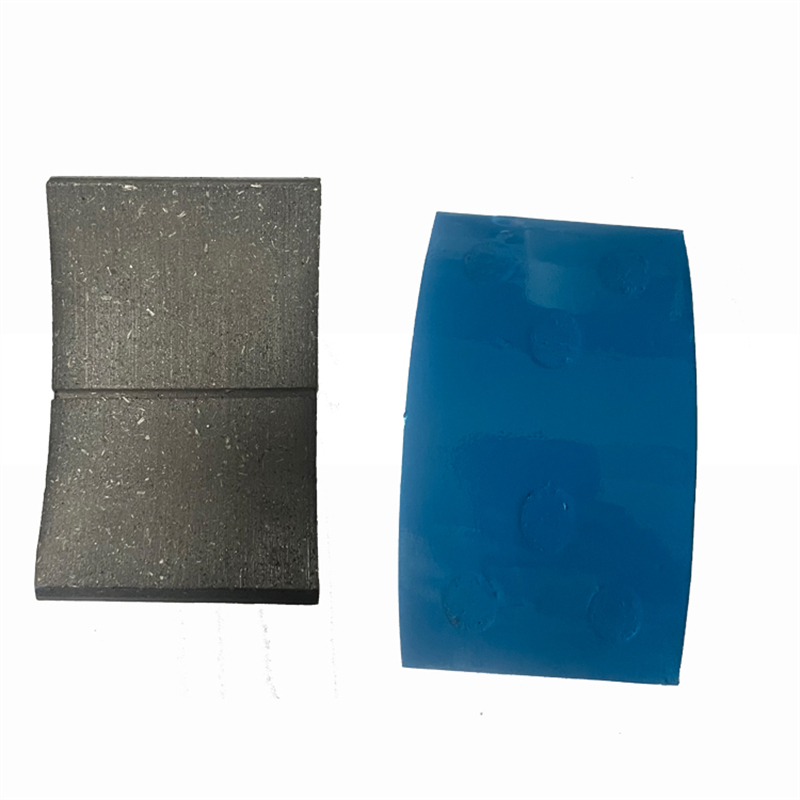

3. softer drum brake

In order to address the issue of outdated and soft material dual brake wheels, MWBIG believes that a softer drum brake band is more suitable. Although its wear resistance is generally low, MWBIG plans to try to modify it in the future to change the defect of low brake band life

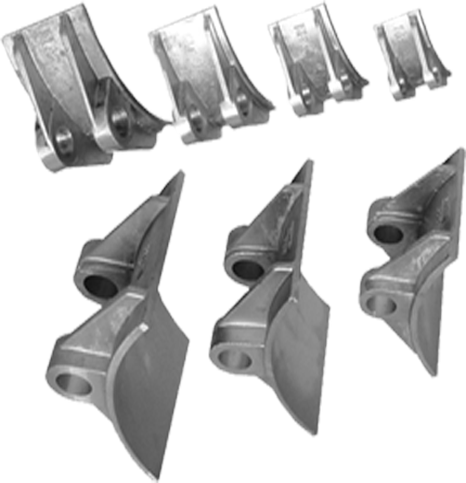

4. Drum brake shoes

The design scheme of MWBIG will adopt an integral molding method to shape higher strength hooves, and fix the drum shaped arc-shaped friction plates on the hooves by pressure heating, and finally assemble them into drum brake shoes