HydroPower Brake Pads

The brake air brake friction plate used for the shutdown braking of hydroelectric generators and steam turbinegenerators is currently facing the following problems:

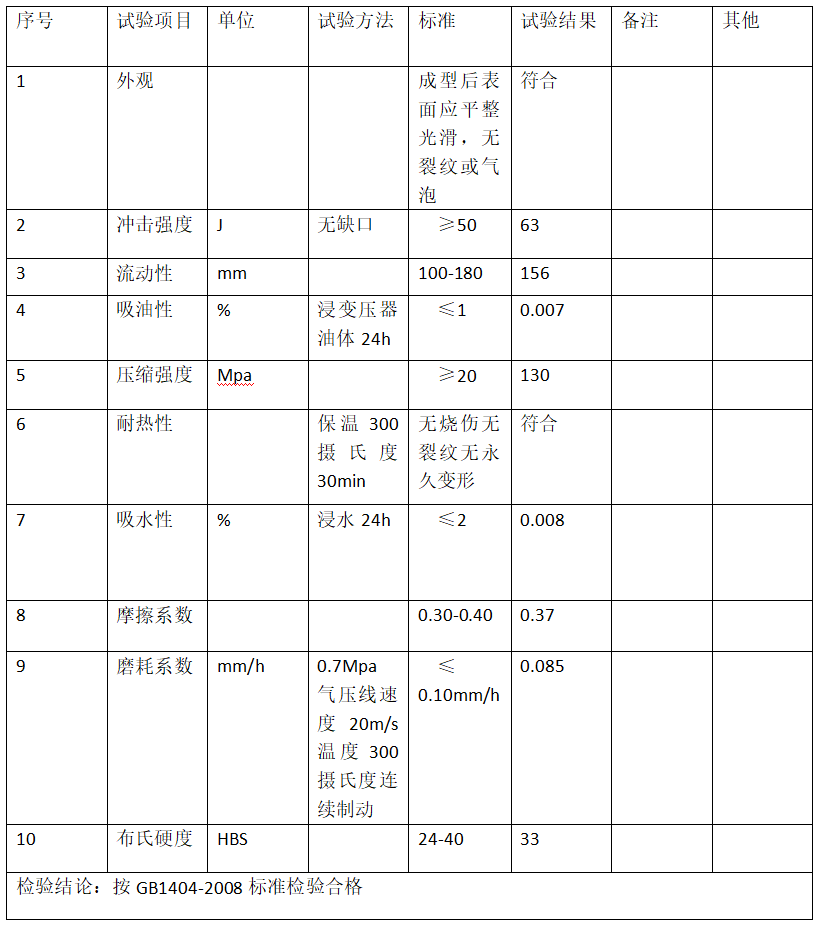

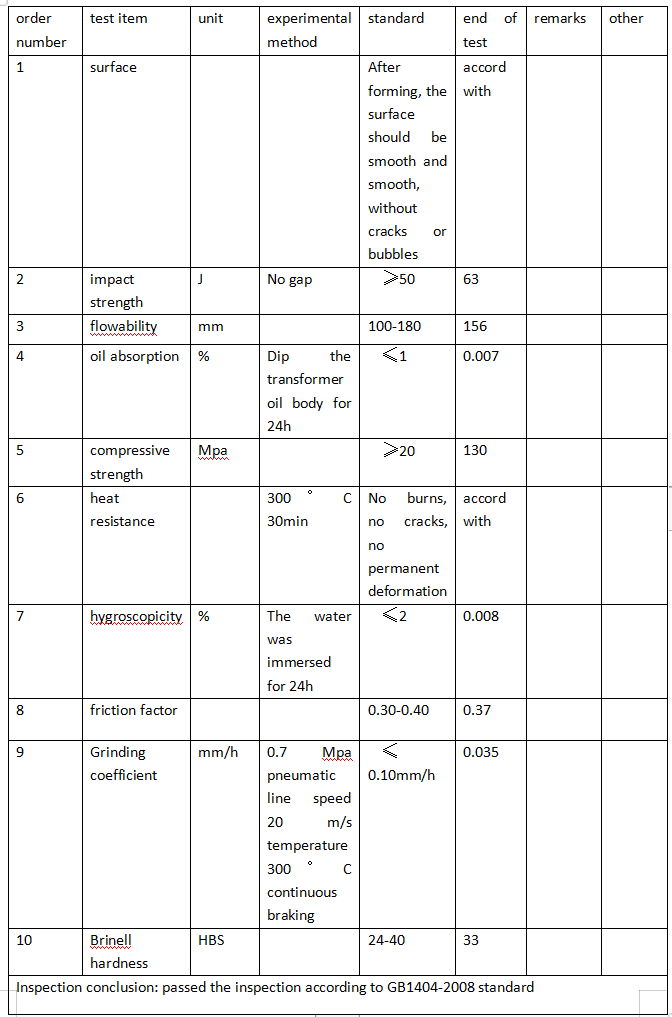

Most of the raw materials used in the current production process of motor brake pads are asbestos, along with metal wires and adhesives. The friction brake pads produced by this process have a low lifespan and generate large amounts of dust during braking. Additionally, due to the presence of irregular and untreated metal wires, sparks are generated during braking friction, which poses a great threat to the workplace.Moreover, asbestos contains carcinogenic substances, which are not conducive to the health of workers. Many customers have raised demands for solutions. MWBIG has developed a production process for asbestos freeand toughened brake pads after more than three years of research and development to address this phenomenon The brake pad has a long service life and greatly avoids sparks generated during friction. VULTURE named this material TGHA9010.

The friction plate ofthe air brake ofthe water turbineand

steam turbine brake made of TGHA9010 material has the

characteristics of wear resistance, pressure resistance

and spark reduction.

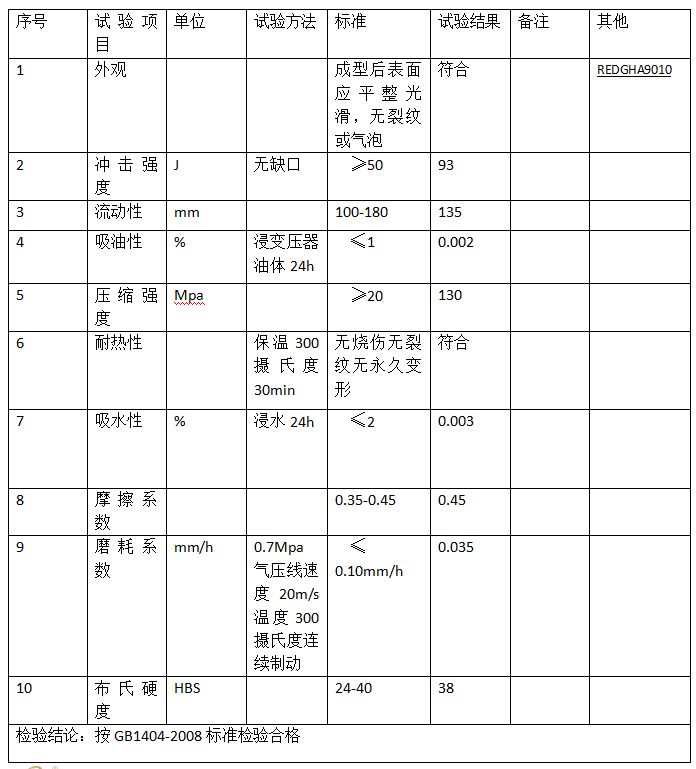

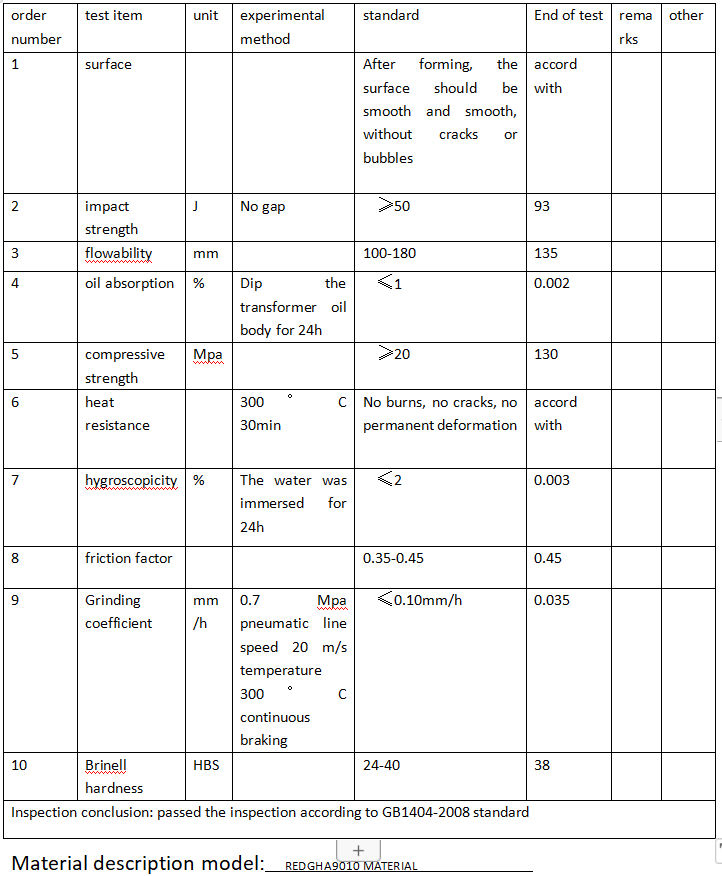

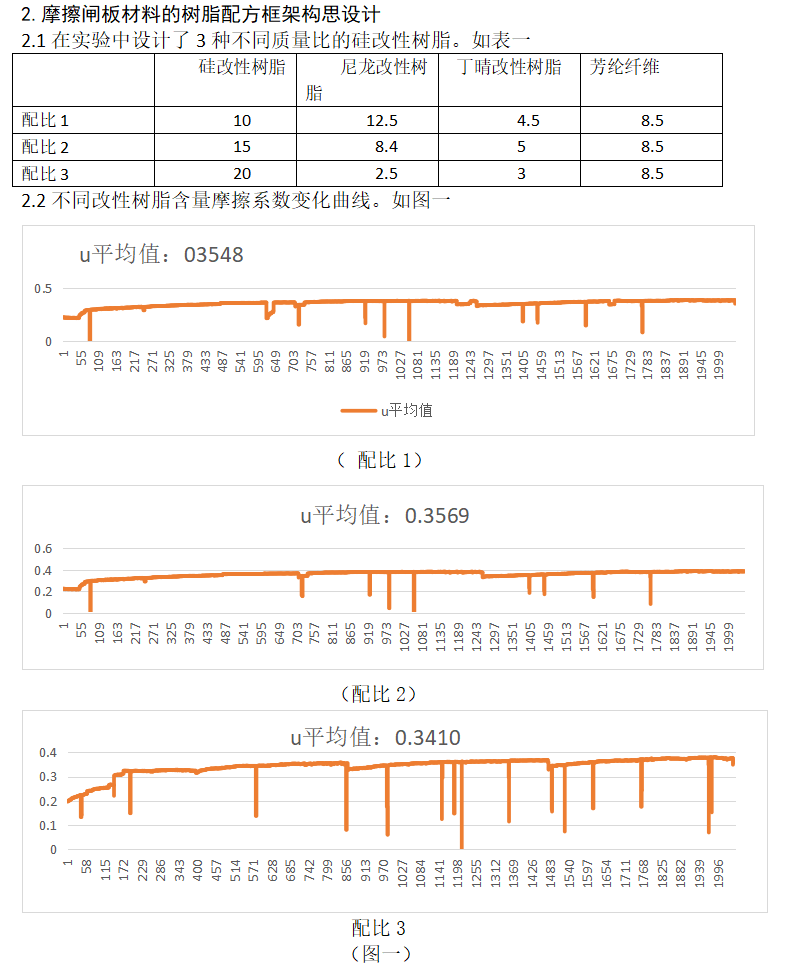

REDGHA9010 material is a higher wear-resistant friction plate material for wind gates proposed by KUMABEAR for hydropower stations with more harsh environments. REDGHA9010 is specifically named TeTao Double Modified Alloy Sintered Material, which abandons the traditional composite material mode and adopts a multi modification method to make the basic material reflect advantageous characteristics and reduce or shield disadvantageous characteristics. Even though REDGHA9010 contains metal elements,the probability and frequency ofspark phenomenon are lower in actual hanging experiments.

REDGHA9010 friction material air brake plate has higher wear resistance, greatly reducing wear rate. Its service life is about 10-20 times that of TGHA9010 material and about 30 times that of ordinary friction materials on the market. Simultaneously maintaining a high and stable coefficient of friction.

REDGHA9010 material friction plates have a complicated production process, high material costs, and relatively expensive prices,REDGHA9010 can reduce the frequency of replacing friction plates for wind gates in hydropower stations, lower personnel workload, and extend the efficiency of mechanical units.

TGHA9010 is still made of REDGHA9010 grade material, and the friction plates manufactured by them have been tested through practice and time, and have received good feedback.